| Sign In | Join Free | My xpandrally.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xpandrally.com |

|

Brand Name : HD Boiler

Model Number : Boiler Economizer

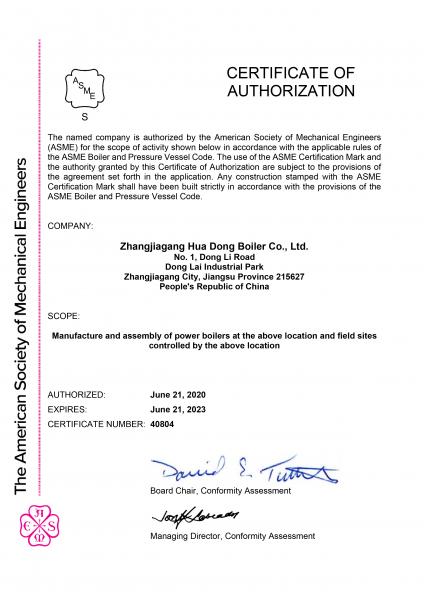

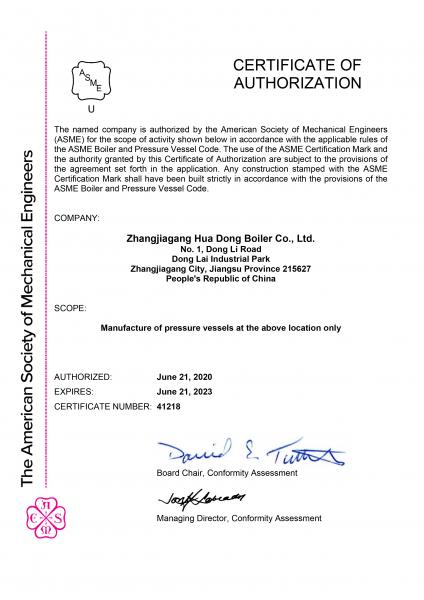

Certification : ISO9001, SGS, ASME, EN

Place of Origin : China

MOQ : 1 Set

Payment Terms : L/C, T/T

Delivery Time : 45 Days

Packaging Details : Iron Packing for Exportation

Material : Steel

Type : Vertical or Horizontal

Fuels : Coal

Standard : ASME

Low / High Pressure Flue Gas Economizer Heat Exchange Devices With Finned Tubes

Introduction

Boiler economizers are heat exchange devices with finned tubes that heat a liquid, sometimes water, up to however sometimes doesn't exceed the boiling purpose of liquid. We can manufacture three types of boiler economizer, bare tube economizer, H finned tube economizer and spiral finned tube economizer. H-finned tube economizer is high efficient heat exchanger economizer which is consisted of H-finned tubes.

Compared with bare tube economizer, H-finned tube economizer can enlarge the heat exchange area and reduce the number of tubes. It also can increase the flue gas flow area in order to reduce the flue gas flow speed and abrasion.

H-finned tube can be made as double H finned tubes , with high rigidness to fit long tube row.

The spiral finned economizer is a newly designed heat transfer equipment, consists of spiral fin tubes to overcome the serious abrasion and short service time.

Working principle

Boiler economizer is kind of heat exchanger to heat the feed water using the flue gas heat. The flue gas coming from the tube outside is up and down cross-flow scrubbing the tube bundle, passing the heat to the tube wall. The water is flowing from bottom to top, and absorts the heat from the tube wall, and its temperature is getting high. This way not only can countercurrent heat transfer to save metal consumption, but also is good for water/steam to flow and exhaust as well as decreasing corrusion. One more, this way works well for dust cleaning.

The structure of boiler economizers

No matter it is boiling or non-boiling type, their structures are the same. They are made of horizontal surpentine pipes, with inlet and outlet headers in parallel. The connection of surpentine pipes and headers are usually finished by welding. Headers are generally places outside of boiler's flue system. If there are lots of heating surfaces in economizer, the general height is quite high. We can divide them into several sections. Shown in picture 3-1, it is divided into two sections, each height is about 1-1.5m, their distance is 0.6-0.8m as overhaul room. In addition, it is needed to set aside 0.8-1m of space for overhaul and clearance of accumulated dust on the heating surfaces.

Specifications

| Description | Boiler economizer |

| Material | Alloy steel, Carbon steel, SA210C ,SA213T22, etc. |

| Material standard | ASTM, EN or ISO etc. |

| Dimension | Customization |

| Weight | Min: 10 ton |

| Smelting Process: | EF+LF + VD |

| Process | Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →rough machining→UT →2nd Heat treatment →finishing machining →Inspection |

| UT standard | ASTM A388 or EN10228, etc |

Certification

Quality Control

1. Impact test and Strength calculation report with applied materials information.

2. 100%NDT(non-destructive inspection) report of steel plate, tube and electrode

3. X-ray, γ-ray and liquid penetrant test inspection report (welding seam): to ensure the quality of the entire boiler

4. Hydraulic test report: ensure the standard working pressure and safety

|

|

Alloy Steel Boiler Economizer With Finned Tubes For Compound Circulation Coal Fired Boilers Images |